REA JET UP

High Resolution, Large Format Inkjet Printing for UK & Ireland

Elevate your marking with the REA JET UP—engineered for high-resolution precision in demanding industrial environments. Delivering up to 1200 dpi, this piezo inkjet printer creates sharp text, barcodes, and graphics on wide range of surfaces. Trusted by UK and Irish industries—from packaging to automotive to construction—it ensures durable traceability and seamless integration with minimal effort.

Up to 108mm

Print height per head

Up to 1200 dpi

IP65 rated

Stainless Steel build

The REA JET UP sets a new standard for high-resolution coding in UK and Irish factories. With print heights up to 700mm using cascaded heads, it’s ideal for large-scale marking on packaging, timber, metal, foam and more.

Its piezo inkjet technology ensures durable, high-contrast results even in dusty or variable conditions (-5°C to 45°C). Easy to integrate into existing lines, this printer delivers consistent quality for traceability, branding, or compliance needs.

Powered by REA’s industry 4.0 TITAN platform, Ethernet, USB and Digital I/O connectivity is standard for easy integration into existing control and database systems.

Key Benefits:

Sharp, bold prints – Up to 1200 dpi for clarity.

Rugged reliability – Built for tough production settings.

Highly versatile – Marks absorbent and non-absorbent surfaces.

Low maintenance – Heavy-duty design maximizes uptime.

High-speed output – Matches fast production lines.

Large print area – Over 100mm print width per head.

Product Applications:

- Alphanumeric texts: Printing of texts, serial numbers, product information or safety instructions on different surfaces

- 1D barcodes, 2D codes and machine-readable codes: Marking of packaging for identification, traceability, quality control and high first-read rates for efficient handling of progress and storage processes

- Logos and pictograms: Application of company logos, danger/safety signs, product images and graphic elements for brand communication, safety and product presentation

- Variable Data: Print date, time, meter readings, shift codes and database content for traceability, quality control and inventory management

- Traceability: Creation of unique identifiers to trace products along the entire supply chain

Secondary packaging: Identification of outer packaging, e.g. B. Cartons and cardboard boxes for optimized warehousing and logistics - Packaging marking: Application in the packaging industry to mark product packaging, both on primary and secondary packaging

- Logistics industry: Used in the logistics industry to identify and track goods in transit, print shipping labels, and improve warehouse and inventory management

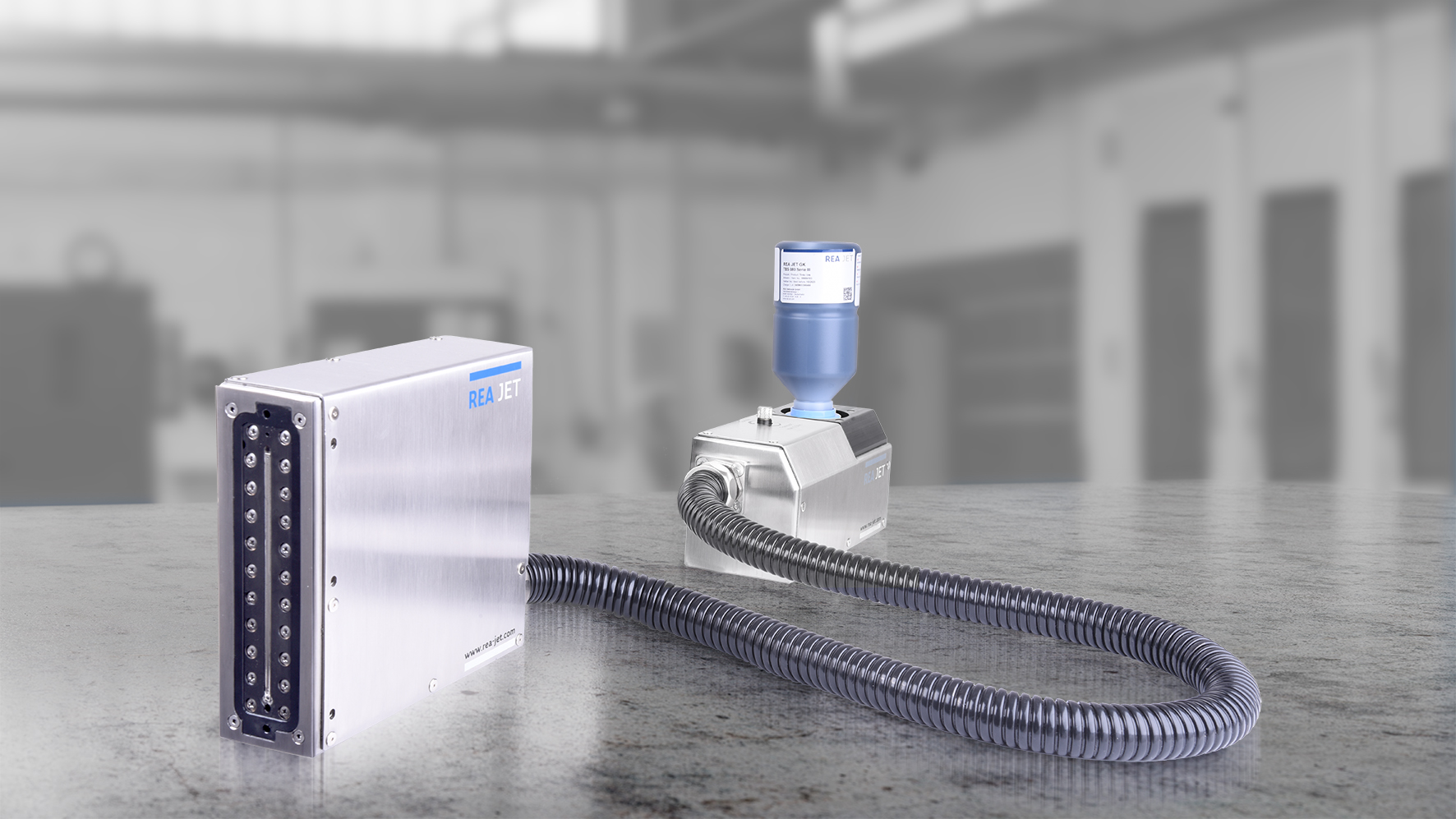

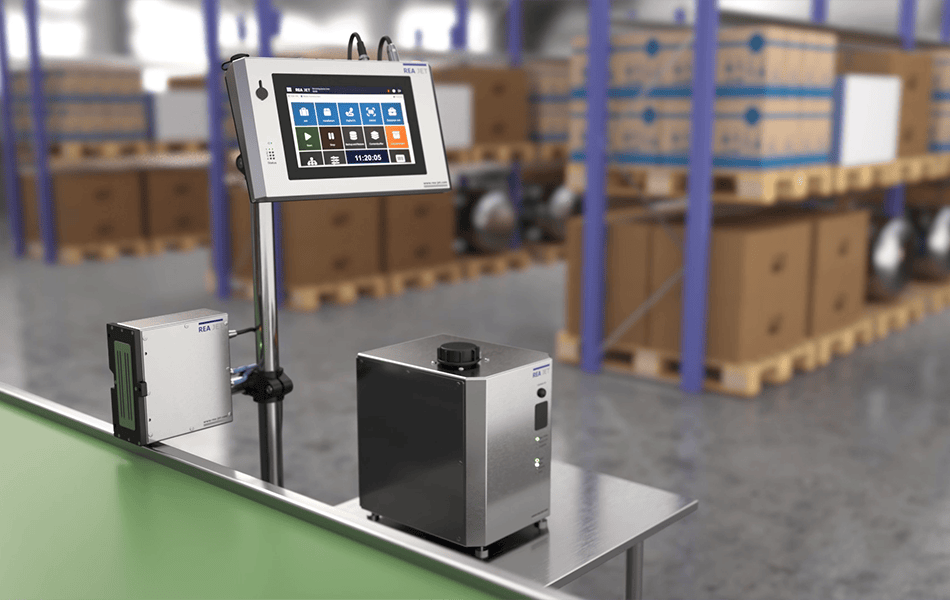

The system

GET TO KNOW THE SYSTEM

Print head

Unmatched Print Quality and Performance

The REA JET UP sets a new benchmark in high-resolution industrial printing. With a maximum print height of 108.37 mm per head and resolutions of up to 1500 dpi horizontally and 360 dpi vertically, it delivers crisp, detailed markings that meet even the strictest compliance standards. From fine text to detailed graphics, every mark is sharp and clear. Better still, production speeds are up to three times faster than previous systems — allowing you to boost output without compromising on quality.

Controller

Flexible Control with Smart Interfaces

Choose from two intuitive controller options to suit your production environment. The Universal Controller features tactile rotary controls, a keypad, and supports two UP print heads for print heights up to 216.74 mm. For a more modern setup, the Universal Touch Controller offers a large 10.1″ touchscreen with a glove-friendly, tile-based interface — no buttons required. It supports up to four print heads for a total print height of 433.48 mm, perfect for larger or more complex applications.

Ink Supply Unit

Efficient Ink Supply, No Interruptions

The REA JET UP’s smart ink circulation system prevents nozzle blockages and keeps print quality consistently high. Inks can be refilled during operation, avoiding downtime and boosting productivity. With RFID-tagged cartridges, the correct ink is always in use, and optional heating ensures smooth operation even in cold environments. Thanks to our fast-drying, patented inks — including UV-curing and oil-based options — you can print directly onto tough surfaces, reducing your reliance on costly, wasteful labels.

Our REA JET DOD 2.0 printing system offers you the choice between two different controllers: the Universal Controller and the Universal Touch Controller. Both controllers enable intuitive operation of the printing system.

With the Universal Controller, you can operate the system using the rotary and push buttons on the control unit. This controller also has a number pad and a cursor block.

The Universal Touch Controller uses the latest technology. It is operated exclusively via the large 10.1" display. With no buttons or knobs, operation is even simpler and more intuitive. The tile-based user interface of the Universal Touch Controller even allows the coding and marking system to be precisely controlled with gloves.

The ability to connect print heads with up to 1024 nozzles to one controller gives you a high degree of flexibility and allows you to configure the printing system to suit your individual requirements.

Our REA JET DOD 2.0 printing system offers you the choice between two different controllers: the Universal Controller and the Universal Touch Controller. Both controllers enable intuitive operation of the printing system.

With the Universal Controller, you can operate the system using the rotary and push buttons on the control unit. This controller also has a number pad and a cursor block.

The Universal Touch Controller uses the latest technology. It is operated exclusively via the large 10.1" display. With no buttons or knobs, operation is even simpler and more intuitive. The tile-based user interface of the Universal Touch Controller even allows the coding and marking system to be precisely controlled with gloves.

The ability to connect print heads with up to 1024 nozzles to one controller gives you a high degree of flexibility and allows you to configure the printing system to suit your individual requirements.

1 / 2