We Know Food

Premium Industrial Marking & Coding Solutions for Traceability in UK Food Manufacturing

What sets REA apart?

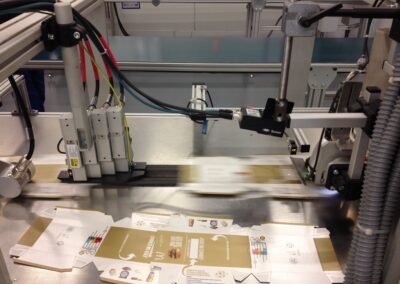

What sets REA UK apart is our independent operations and engineering wing, developing bespoke sub-solutions like inline vision to check each mark, integration with line PLC’s for operator-free control, automation of the marking systems, and centralised software for full factory-wide visibility of all REA solutions with bespoke function modules for every need. Unlike competitors, our systems boast long lifespans exceeding 10 years in wet, high-speed environments, with food-safe certified inks ensuring GS1-compliant traceability that meet UK and EU regulations.

Application List:

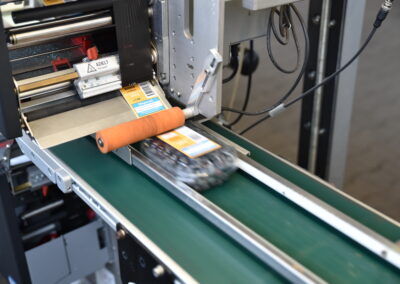

- 1D and 2D Codes: Achieve high-contrast, durable markings for traceability, with verification for compliance in food supply chains.

- Marking on Films, Bags, Glass, and Plastics: Deliver versatile coding on varied packaging, using quick-drying inks for wet surfaces.

- Variable Data Printing: Apply dynamic content like batch numbers and manufacturing dates, enhanced by automation for efficiency.

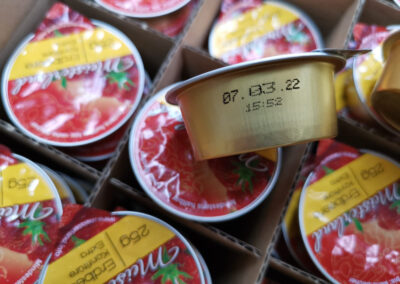

- Best Before and Manufacturing Date: Ensure legible dates on products, supported by inline vision for real-time checks.

- Label Replacement: Reduce costs with direct marking alternatives, backed by centralised software for oversight.

- Complete Traceability: Integrate end-to-end solutions, with PLC links for operator-free control in high-speed lines.

Industry Challenges List:

- Hygienic and Wet Environments: Marking on damp packaging risking smudging—solved by our food-safe, contact-free systems that only put ink as required on your products, not your production line.

- High-Speed Production: Maintaining codes at rapid paces without downtime, addressed via automation and PLC integrations.

- Regulatory Compliance: Meeting UK/EU & GS1 standards for coding, handled through verification and centralised software.

- Diverse Packaging Materials: Inconsistent adhesion on films/plastics, mitigated by quick-drying inks and inline vision checks.

- Supply Chain Errors: Gaps leading to recalls, countered by full visibility and bespoke function modules.

- Food Packaging Safe: REA has a range of Food Packaging Certified Safe inks which are also operator and environmentally friendly.

- 99.9% Uptime Requirements: Our maintenance free technologies ensure 99.9% uptime, measured over decades.

Frequently asked questions

What marking challenges do UK food manufacturers face?

Strict control standards and high throughput, but REA UK’s high speed, food-safe systems ensure clear traceability without contact, no matter the volume.

How does REA UK ensure traceability in food production?

Our GS1 Approved Verifiers and Marking products ensure every mark is accurate and our solutions offer 99.9% uptime.

What sub-solutions does REA UK offer for food?

Inline vision to check each mark, integration with line PLC’s for operator free control, automation of the marking systems and centralised software for full factory wide visibility of all REA solutions with bespoke function modules for every need.

Are REA systems suitable for hygienic food lines?

Yes, with edible food grade and food packaging safe inks, our solutions ensure the print is only ever on your product, not your production line.

Are REA consumables recyclable?

Yes, our ink cartridges most certainly are recyclable. REA UK provide cartridge collection bins and handle the logistics for you, ensuring you remain green and stay focussed on what matters.

What is Verification and Why Does it Matter?

Verification differs from inline vision checks in that it creates replicable scan conditions according to ISO standards and produces an ISO/GS1 compliant report. Read more about Verification in our recent blog posts

How can I get started with REA UK for food marking?

Contact us for a free assessment—our experts tailor solutions to your needs, from inkjet to laser, ensuring premium ROI.

We’re here to help

Hi! My name is Josh, I’m the Solutions Engineer at REA UK.

Do you have any questions about what we do? Would you like to learn more about our products?

Get in touch today!