We Know Wood

Premium Industrial Marking & Coding Solutions for Traceability in UK Wood & Timber Manufacturing

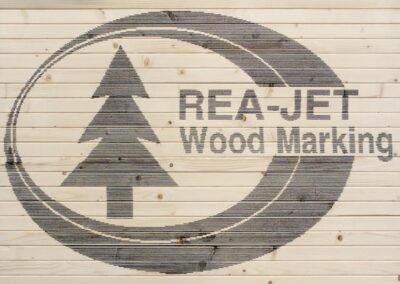

At REA UK, we deliver unbreakable traceability and identification for wood and timber manufacturers across the UK and Ireland, specializing in high-quality, contact-free coding and marking on diverse products—from timber mills’ logs and treated/planed/graded/construction timber to wood pellet bags, chipboard, OSB board, plyboard, roof trusses, furniture, kitchen cupboards, and countertops, pallets and more. Our German-engineered solutions tackle the demands of harsh processes like sawing, planing, and extrusion, ensuring precision, durability, and efficiency in dusty environments. With over 40 years of expertise rooted in heavy industries, we provide robust inkjet, laser, labelling, and verification systems that integrate seamlessly, reducing scrap and enhancing supply chain visibility for premium compliance.

What sets REA apart?

What sets REA UK apart is our independent operations and engineering wing, developing bespoke sub-solutions like inline vision to check each mark, integration with line PLC’s for operator-free control, automation of the marking systems, and centralised software for full factory-wide visibility of all REA solutions with bespoke function modules for every need. Unlike competitors, our systems boast long lifespans exceeding 10 years in rugged settings. If you can dream of ways to mark timber, we probably do it already, tailored to UK forestry standards like FSC/PEFC.

Key Automotive Marking Applications:

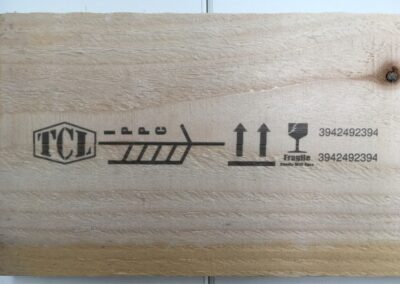

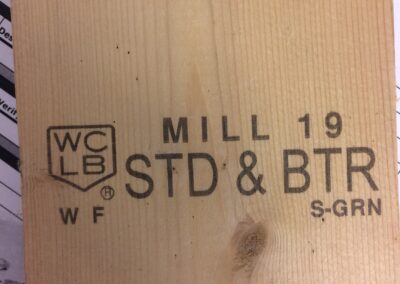

- Grading & Stack Marking on Logs/Timber: Apply high-contrast marks for grading/traceability on edges/stacks in mills, or apply your logo to stacks of timber for larger than life brand exposure.

- Slat & Foot Marking: Mark slats/ends for identification, including logos, delivered by our high resolution, maintenance free systems.

- Board Marking: Whether it is OSB, Chipboard, MDF or Plyboard, our solutions can do edge marking of boards as thin as 6mm or print on the top/underside of the board to apply large logos, symbols, handling or installation instructions, grading and traceability info.

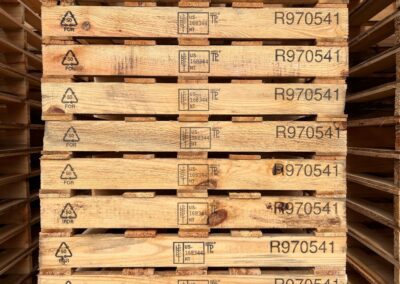

- Pallet Branding & ISPM Marking: Remove branding irons from your site and mark directly on the pallet blocks or bearers with our high definition, EPAL approved solutions. This helps increase throughput, reduce downtime and eliminate fire risk all while lowering energy bills.

- Wood Pellets: Print on wood pellet bags for traceability.

- Traceability and Branding on Furniture/Cupboards/Countertops: Mark logos, specifications, symbols and traceability on finished wood products.

- Multi-Coloured Dots/Lines for Differentiation: Mark for sorting/quality on timber, supported by quick-drying inks.

Industry Challenges List:

- Harsh Environments: Marking on damp/uneven timber with vibration and dust in the production environment. Our IP65 print solutions are built for this.

- High-Speed Mill Processes: Maintaining accuracy in sawing/planing without downtime, our solutions can maintain print legibility at production line speeds up to 600m/minute.

- Damaged, bowed or knotted slats: Our heavy duty sleds allow our solutions to cope with uneven, broken or bowed timber without damage to the print heads.

- Compliance for Sustainability: Meeting all regulatory body standards in timber for marking requirements.

- Error Reduction in Supply Chains: Gaps leading to scrap/recalls, countered by bespoke modules and inline vision checks.

Frequently asked questions

Can REA Print IPPC/ISPM Marks?

What is the fastest REA systems can print on timber?

How long are REA prints expected to last?

What sub-solutions does REA UK offer for wood/timber?

Are REA systems suitable for harsh timber lines?

How can I get started with REA UK for timber marking?

We’re here to help

Hi! My name is Josh, I’m the Solutions Engineer at REA UK.

Do you have any questions about what we do? Would you like to learn more about our products?

Get in touch today!

![Wood and Timber- HR Glued laminated timber[15]](https://www.rea-jet.co.uk/wp-content/uploads/2024/12/HR-Glued-laminated-timber15-400x284.jpg)