We Know Chemical

Premium Industrial Marking & Coding Solutions for Traceability in UK Chemical Manufacturing

At REA UK, we provide unbreakable traceability and identification for chemical manufacturers across the UK and Ireland, specializing in high-quality, contact-free coding and marking in hazardous and corrosive environments. Our German-engineered solutions address the demands of processes like filling, packaging, and labelling, ensuring precision, safety, and efficiency in regulated production lines. With over 40 years of expertise rooted in heavy industries, we offer robust inkjet, laser, labelling, and verification systems that integrate seamlessly, reducing errors and enhancing supply chain visibility for premium compliance.

What sets us apart?

What sets REA UK apart is our independent operations and engineering wing, developing bespoke sub-solutions like inline vision to check each mark, integration with line PLC’s for operator-free control, automation of the marking systems, and centralised software for full factory-wide visibility of all REA solutions with bespoke function modules for every need. Unlike competitors, our systems boast long lifespans exceeding 10 years in aggressive chemical settings, with features that ensure chemical-resistant performance and GS1-compliant traceability tailored to UK regulations.

Marking Applications:

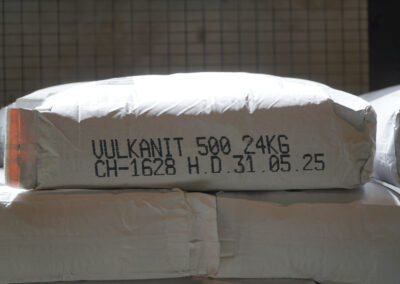

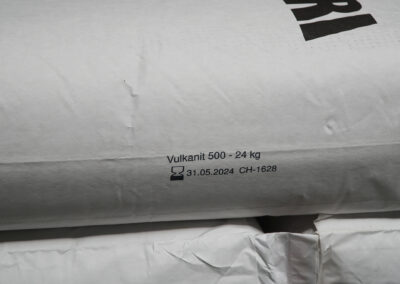

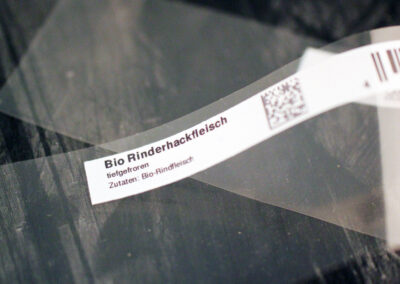

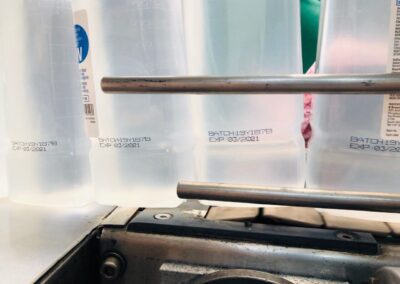

- 2D Codes, Barcodes, Batch Codes, and Best Before Dates: Achieve clear, durable markings on packaging for traceability, supported by high-resolution inkjet for quick application in filling lines.

- Full Colour Printing of Warning or Compliance Symbols: Full, high speed, inline colour printing of symbols onto almost any substrate, including dissolvable membranes.

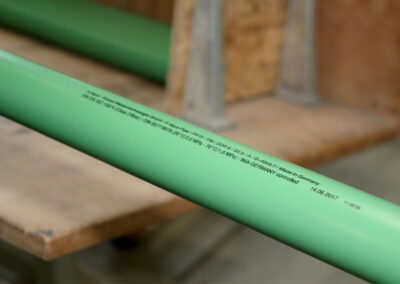

- High-Resolution Printing on Labels, Cartons, and More: Deliver precise information on various substrates, with laser options for permanent and indelible marking in corrosive areas. Deliver precise information on various substrates, with laser options for permanent and indelible marking in corrosive areas.

- Anti-Counterfeiting Solutions: Protect products with secure codes and verification, enhanced by inline vision for real-time authenticity checks.

- Contact-Free Printing of Material Specification, Safety, and Use Information: Apply essential data without contact, ideal for hazardous zones, using automation for operator-free efficiency.

- Reducing Failure Costs in the Warehouse and Field: Minimize errors with integrated traceability, backed by centralised software for factory-wide oversight and bespoke modules.

Industry Challenges List:

- Hazardous and Corrosive Environments: Marking on aggressive surfaces risking degradation—solved by our chemical-resistant inks and contact-free systems.

- Regulatory Compliance and Safety: Meeting UK/GS1 standards for batch tracking in volatile areas, addressed via verification and PLC integrations for automated control.

- High-Volume Packaging Speeds: Maintaining legible codes without downtime, mitigated by quick-drying formulas and marking automation.

- Anti-Counterfeiting Risks: Protecting against fakes in global supply chains, countered with secure 2D codes, UV Fluorescent marks and inline vision checks.

- Error-Prone Traceability: Gaps in identification leading to recalls, handled through centralised software for full visibility and bespoke function modules.

Frequently asked questions

What marking challenges do UK chemical manufacturers face?

Hazardous environments cause degradation, but REA UK’s chemical-resistant systems ensure durable traceability without contact.

Are REA Inks chemical resistant?

Our huge portfolio of inks include a range of chemically resistant options, including chemically resistant labels, and our lasers offer indelible marking options.

What sub-solutions does REA UK offer for chemicals?

Inline vision to check each mark, integration with line PLC’s for operator-free control, automation of the marking systems and centralised software for full factory wide visibility of all REA solutions with bespoke function modules for every need.

Are REA systems suitable for corrosive environments?

Yes, we use stainless steel and aluminium in all our builds, ensuring our solutions are resistant to corrosive environments and ensuring long system lifespans.

How can I get started with REA UK for chemical marking?

Contact us for a free assessment—our experts tailor solutions to your needs, from inkjet to laser, ensuring premium ROI.

We’re here to help

Hi! My name is Josh, I’m the Solutions Engineer at REA UK.

Do you have any questions about what we do? Would you like to learn more about our products?

Get in touch today!